- Homepage

- production

- Industry

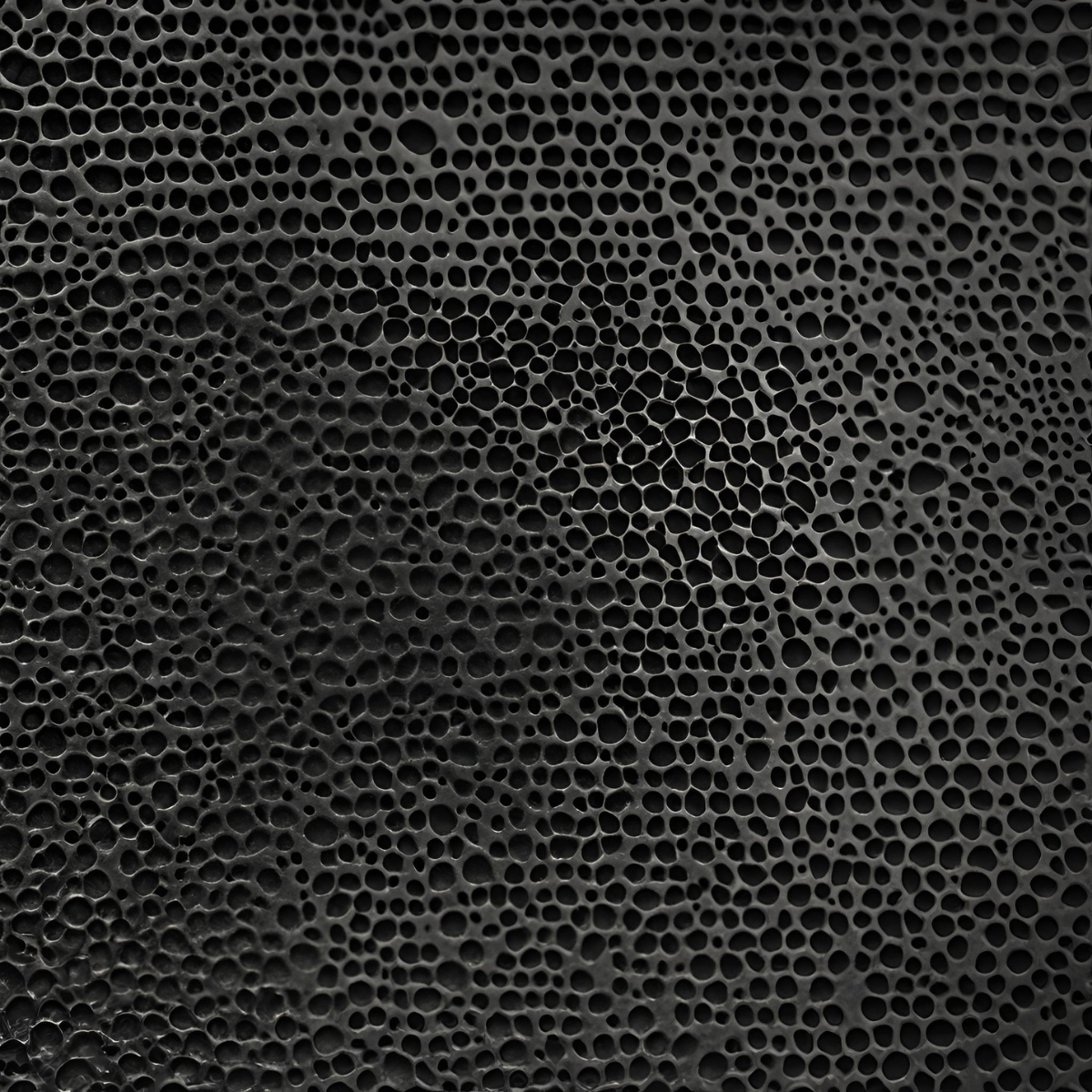

FAST/SPS: No organic binder required, ensuring higher material purity for parts

Ceramics

Silicon carbide (SiC), Boron carbide (B4C), Zirconium carbide (ZrC), Zirconium diboride (ZrB2), Zirconia (ZrO2), Silicon nitride (Si3N4), Alumina (Al2O3), Lead zirconate titanate (PbZrO3), Titanium diboride (TiB2), Tungsten carbide (WC-Co), High entropy ceramics (HEC) ...

Metals

Pure metals, , Copper (Cu), Aluminum (Al), Iron (Fe), Alloys based on iron, nickel, copper, aluminum, titanium, chrome, High entropy alloys (HEA) ...

Precious Metals

Gold,

Silver

Platinum,

Palladium

Composite Materials

Ceramic and Metal Matrix Composites, Ceramic Matrix Composites (CMCs), Common CMC, Short Fibers, Long Fibers, and Nanomaterials ...

Ultra-High Temperature Ceramics (UHTC)

Norimat offers multiple solutions to meet the challenges of industry and manufacturing.

The FAST/SPS process enables ultra-hard refractory materials to be densified at very high temperatures in record time (<1 hour). Thanks to a detailed understanding and precise control of sintering conditions, Norimat can produce materials with a density of over 99.9%.

Density over 99.9%.

FAST/SPS for UHTC

IMPROVED MECHANICAL PROPERTIES

INCREASE SERVICE LIFE

COMPLY WITH INTERNATIONAL HEALTH AND SAFETY LEGISLATION

Thanks to the FAST/SPS process, the production of tungsten carbide cutting inserts is significantly improved and complies with the latest international manufacturing regulations, such as REACH.

Industrial parts can be manufactured without cobalt binders and can incorporate composite or functional gradient materials.

APPLICATIONS

- CUTTING TOOLS (MACHINING, FORGING, ETC.)

- SPRAYING TARGETS

- SPRAY NOZZLES

- BRAKING DISCS

- SPECIALISED ABRASIVES

- MECHANICAL SEALS

- SPECIFIC APPLICATIONS IN HARSH ENVIRONNEMENT

OTHER APPLICATIONS REQUIRING INCREASED RESISTANCE - High-level expertise in the development and production of high-performance ceramics

BULLETPROOF VESTS

Lighter equipment. Development of multiple materials and microstructure control

LIGHT VEHICLE ARMOURING

High mechanical properties: Silicon carbide (SiC): +30% hardness, +40% toughness.

COMPOSITE MATERIALS

Military-quality materials for ballistic applications (SiC, B4C, ZrB2, etc.)

NORIMAT CAN SUPPORT YOU FROM THE FEASABAILITY STUDY TO THE SERIAL PRODUCTION OF YOUR HIGH-PERFORMANCE CUTTING TOOLS

- Total densification of the material

- Elimination of cobalt, compliance with REACH legislation

- Improved mechanical properties: tungsten carbide: hardness +15%, toughness +10%.