- Homepage

- Articles

Download below FAST/SPS videos and articles

Spark Plasma Sintering (SPS), also known as Field Assisted Sintering Technique (FAST), Pulsed Electric Current Sintering (PECS), or Plasma Pressure Compaction (P2C), is a rapid sintering technique that utilizes direct electrical current to rapidly heat and densify materials.

Norimat Spark Plasma Sintering Event

From Powder to Production-Ready Parts

From Powder to Production-Ready Parts

We support our clients every step of the way — from material selection to validated parts ready for production.

In this video, our Materials Project Leader Céline LARIGNON, PhD shares how Norimat’s products and services help accelerate development through:

- Selection of materials and densification conditions

- Scaling up to validate performance under representative use conditions

- Choosing the best manufacturing route to meet geometry, tolerances, and property requirements

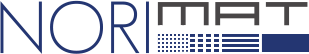

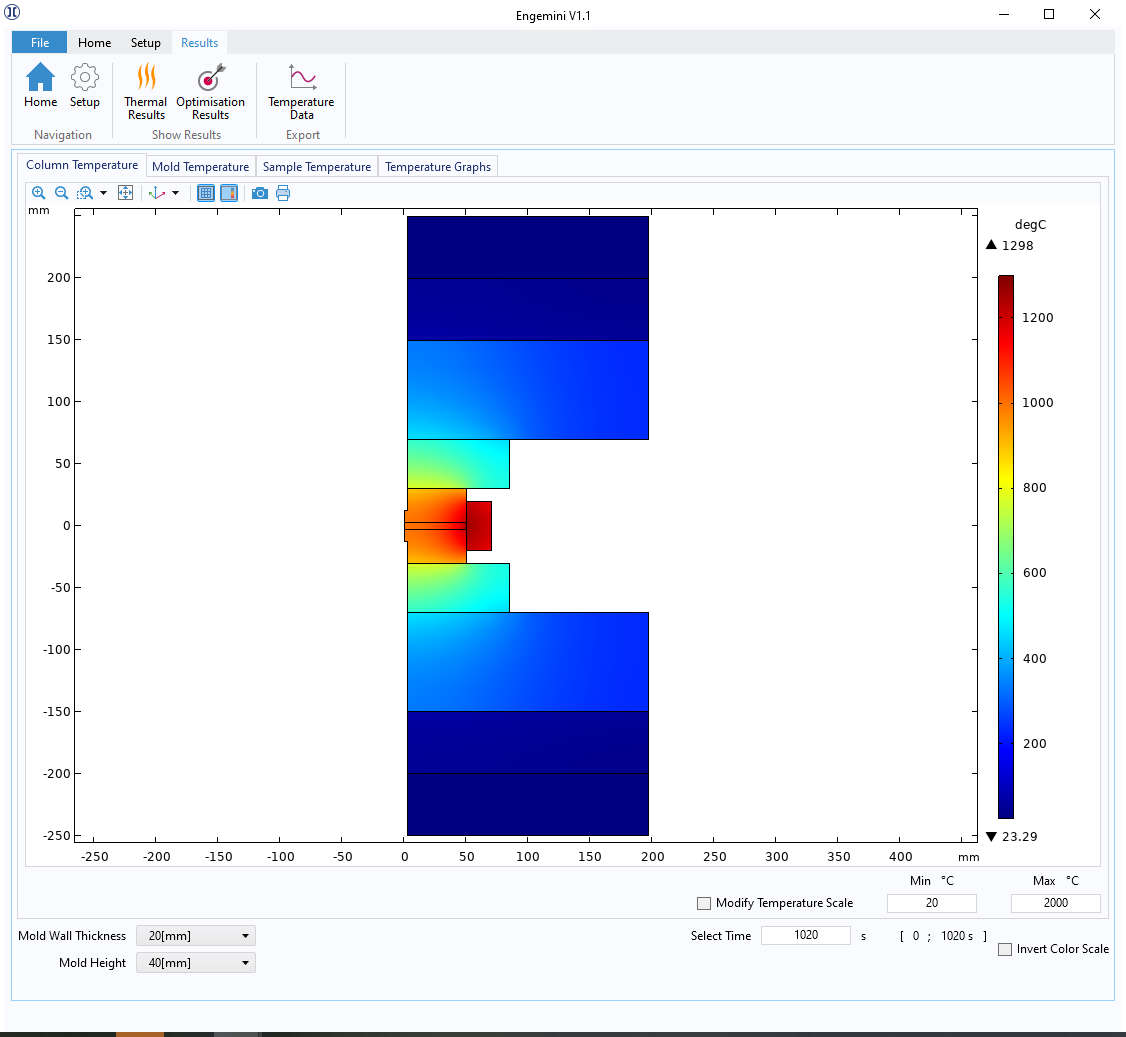

Modeling and Simulation in the Context of SPS

The importance of modeling and simulation in the context of SPS industrialization

We believe that modeling isn't just a support function — it's a driver of efficiency, precision, and cost reduction in advanced manufacturing.

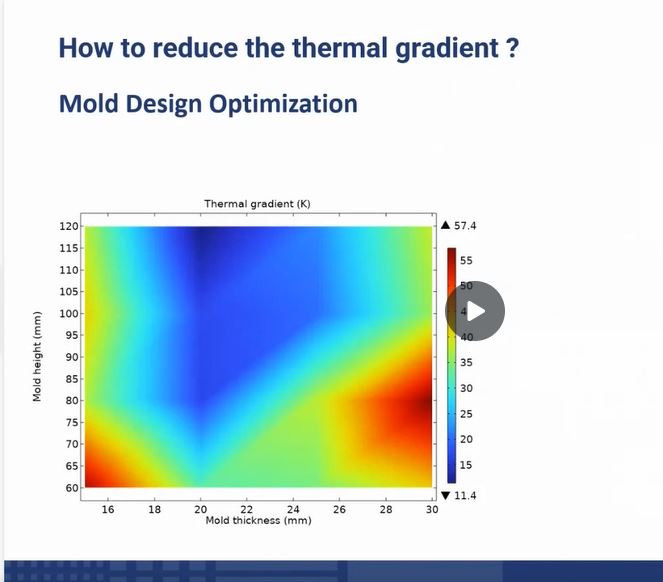

Our modeling and simulation capabilities allow us to:

- Understand and control temperature gradients within the sample and tooling

- Test different setups and configurations without financial implications

- Reduce development time during scale-up or when switching between SPS machines

In this short presentation, our Head of Modeling, Jennifer Mackie, PhD, shares how simulation is accelerating the industrial deployment of Spark Plasma Sintering.

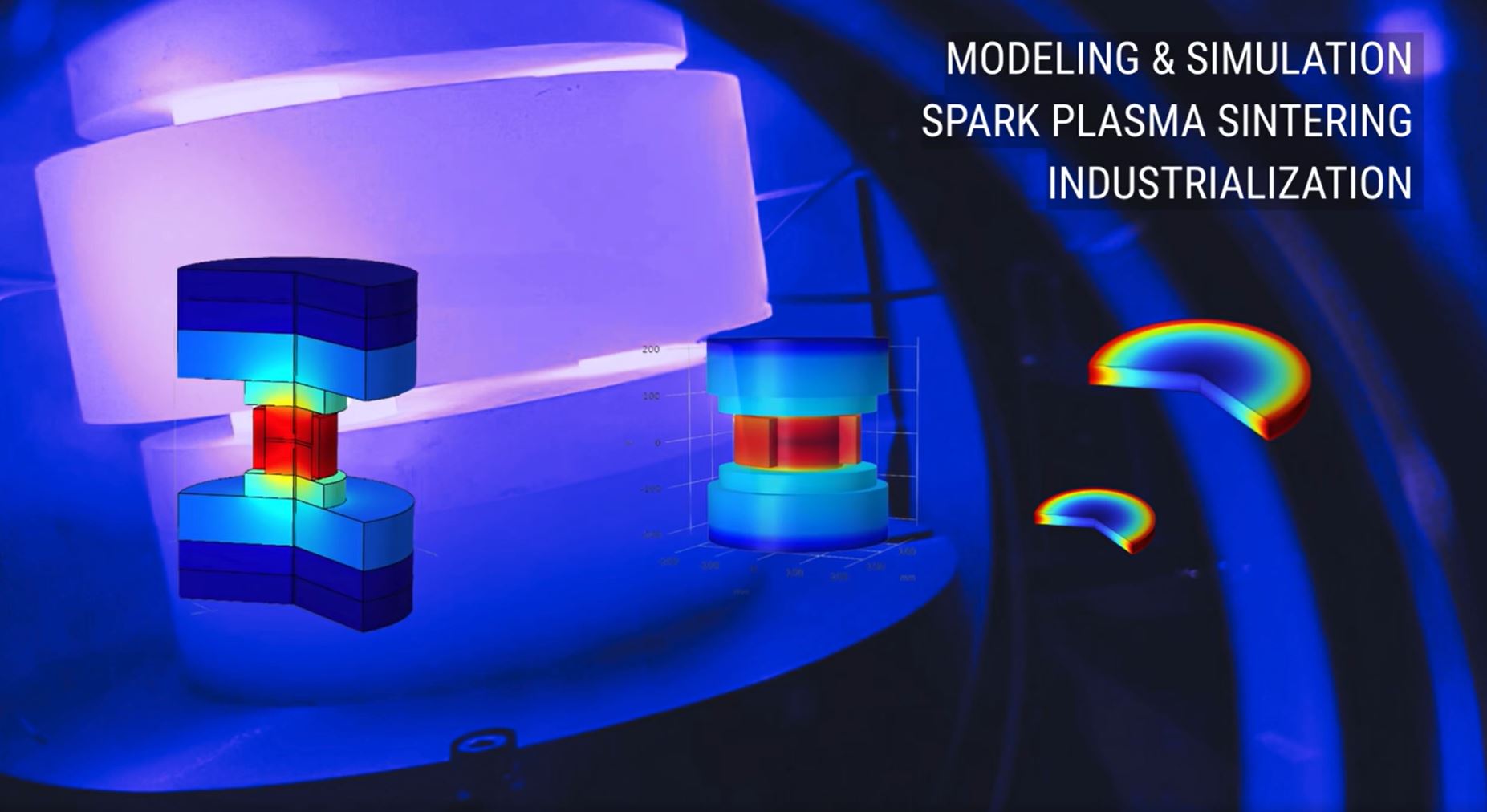

Near-net shape part production

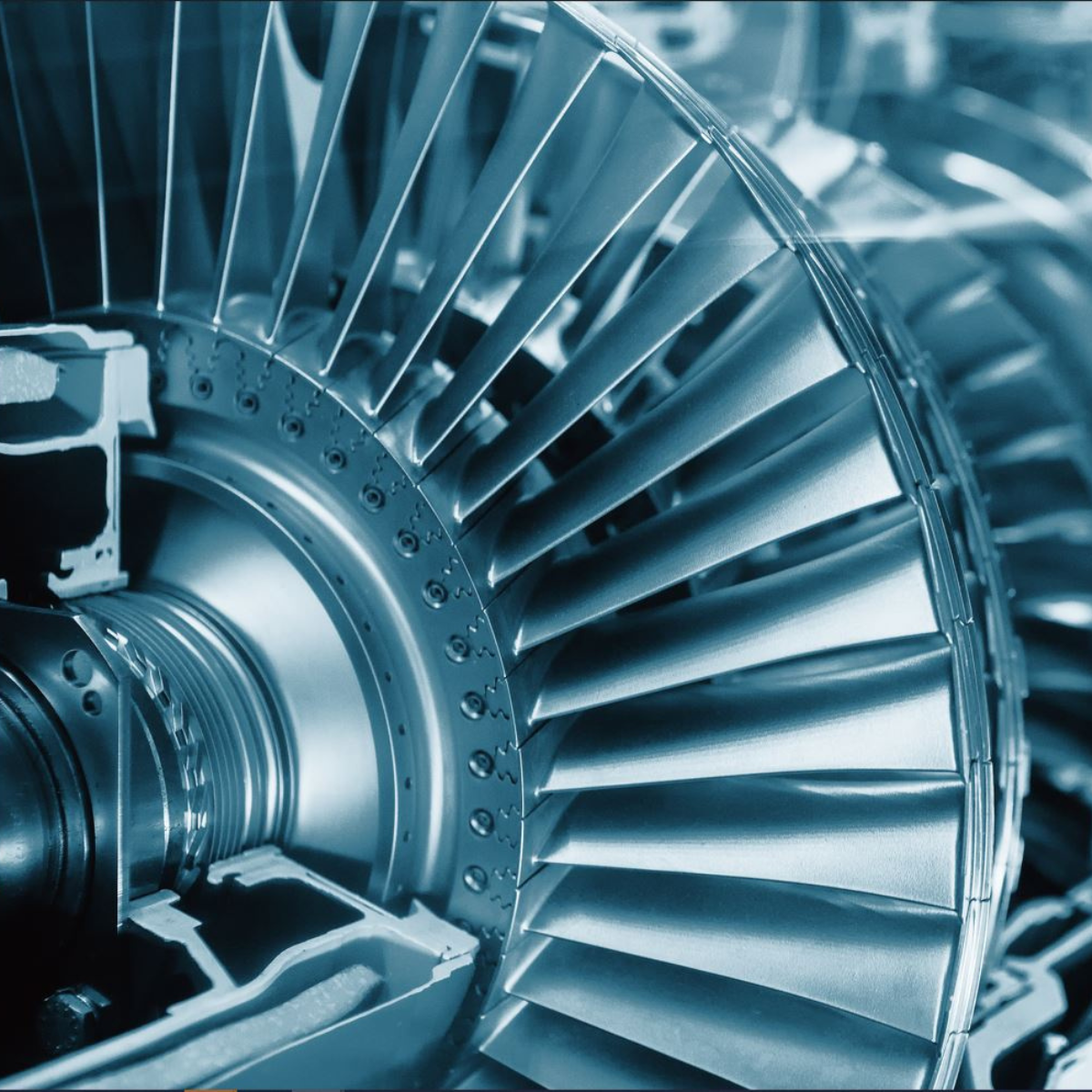

The new era of Spark Plasma Sintering: Near-net shape part production with enhanced performance

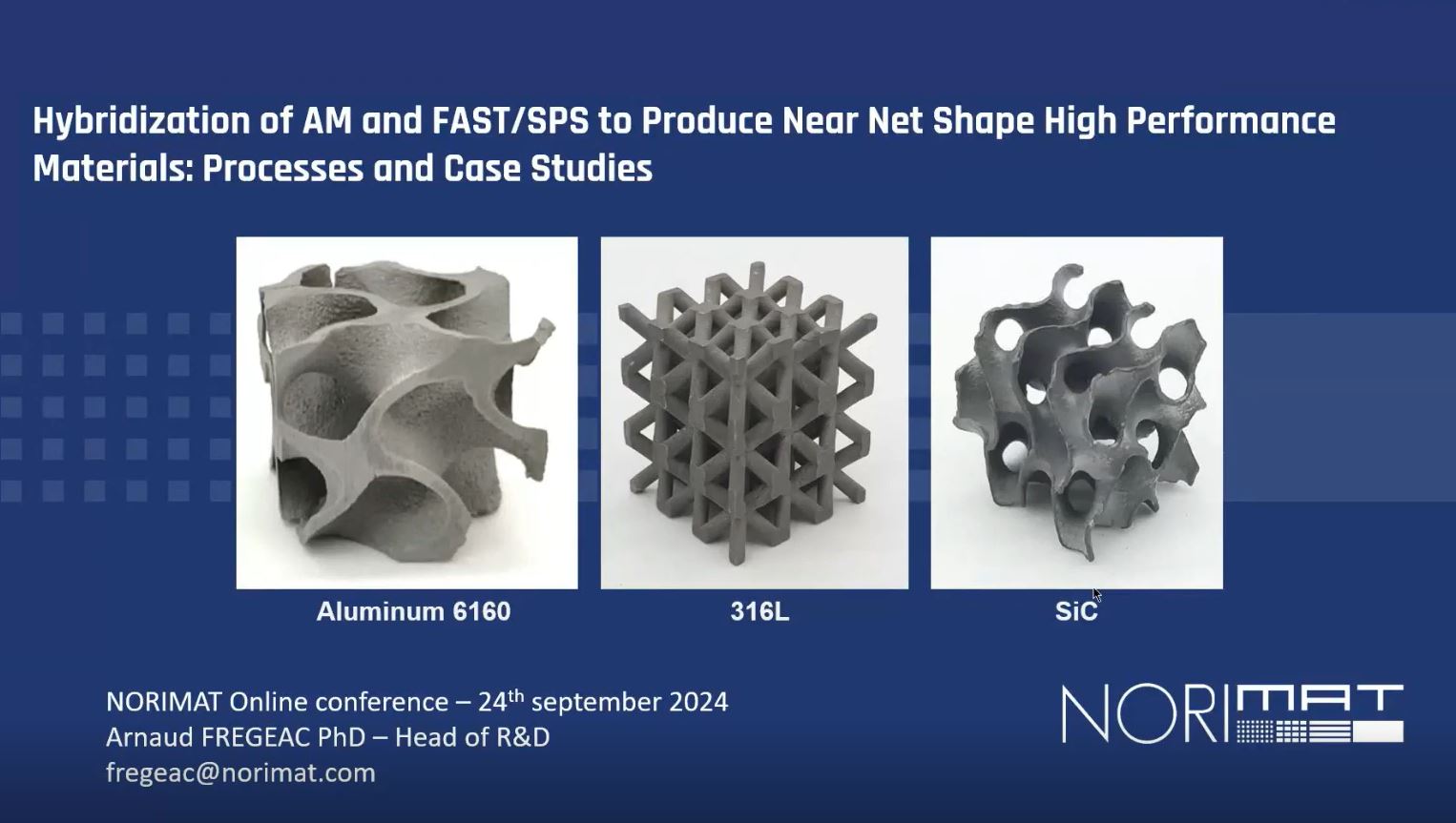

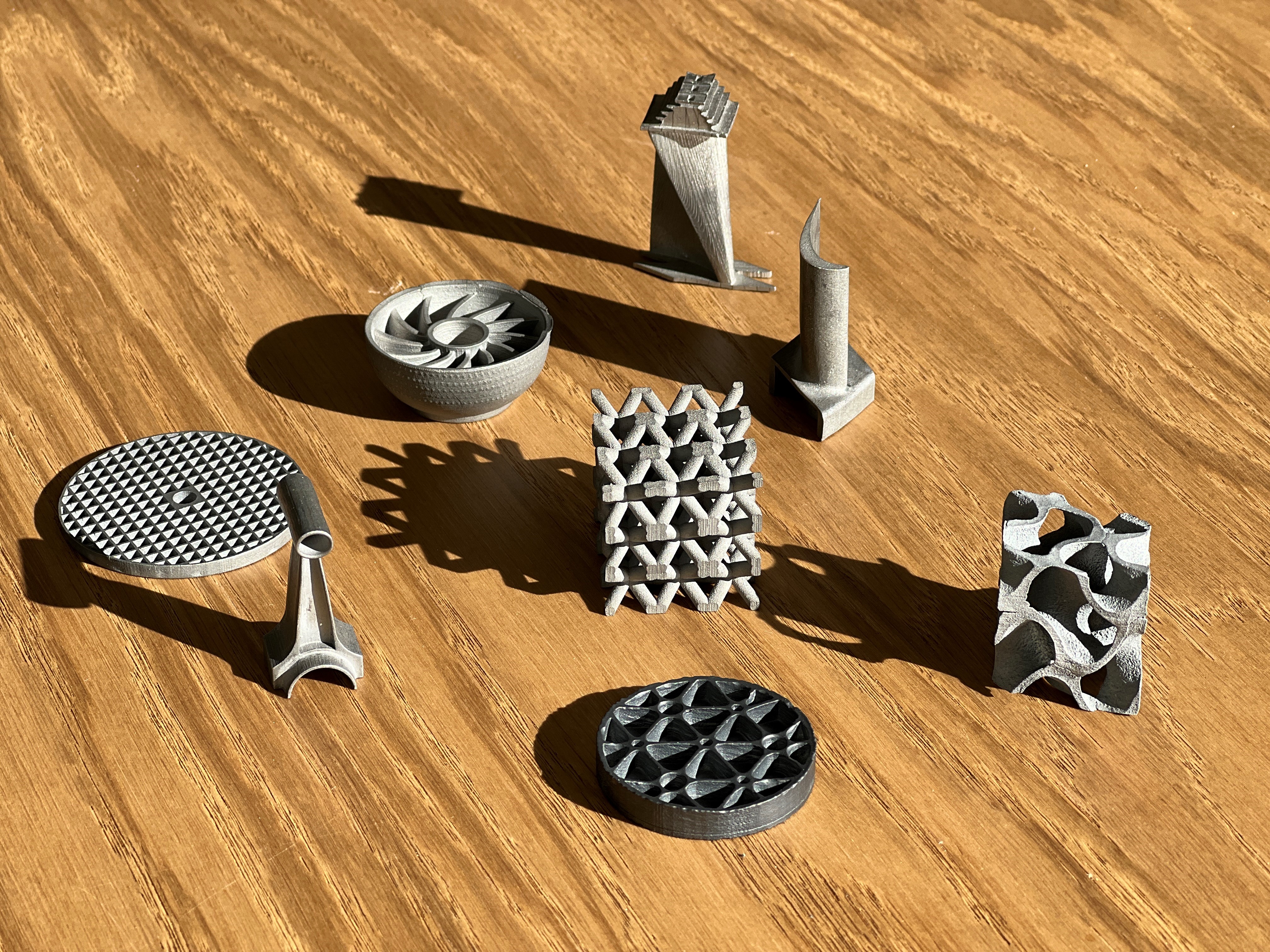

Norimat's R&D team is pushing the boundaries of advanced manufacturing by hybridizing Additive Manufacturing with Spark Plasma Sintering (SPS/FAST).

This innovative approach allows us to:

- Manufacture near-net shape parts

- Achieve superior mechanical properties compared to conventional methods

- Deliver parts from powder to final shape in under 1 hour

Want to dive deeper? Discover this short presentation by our Head of R&D, Arnaud Fregeac, PhD: "Transforming SBAM-printed materials into high-performance parts with FAST/SPS: from prototype to production"

Norimat Spark Plasma Sintering Event

The Latest Advancements in SPS Technology

On March 13, 2025, Norimat hosted its Spark Plasma Sintering (SPS) event in Toulouse, marking a significant milestone in advanced materials manufacturing. The event brought together industry leaders, researchers, and partners to explore the latest advancements in SPS technology and its transformative impact on various sectors.

FIRST SPARK PLASMA SINTERING EVENT DEDICATED TO PRODUCTION

Hosted by Norimat on March 13 in Toulouse

This event will bring together industry leaders, researchers and partners to explore the latest advances in Spark Plasma Sintering (SPS) and its impact on advanced materials.

Webinar : "Industrial product development by Spark Plasma Sintering (FAST/SPS)

From material validation to 3D part manufacturing, how does NORIMAT break through geometrical and dimensional technological barriers?

Video - Comsol KEYNOTE TALK

Spark Plasma Sintering (FAST/SPS) Modelling and Digital

How Numerical Simulation can be Used to Improve the Densification of Materials by FAST/SPS

Hybridization of AM and FAST/SPS to Produce Near Net Shape High Performance Materials

Processes and Case Studies

Spark Plasma Sintering Online Conference

Webinar Arnaud Fregeac Ph.D: Dr. Arnaud Fregeac, Head of the R&D Department at Norimat, and expert in the manufacturing of 3D-printed high-performance materials.

Video Printing UHTC parts by Binder Jetting, relying on digital technology to predict deformation

Digital technology to predict deformation

The missing piece of the puzzle:

Printing UHTC parts by Binder Jetting, relying on digital technology to predict deformation, densifying these pure parts to 100% using FAST/SPS technology, offers more competitiveness and a decisive competitive advantage.

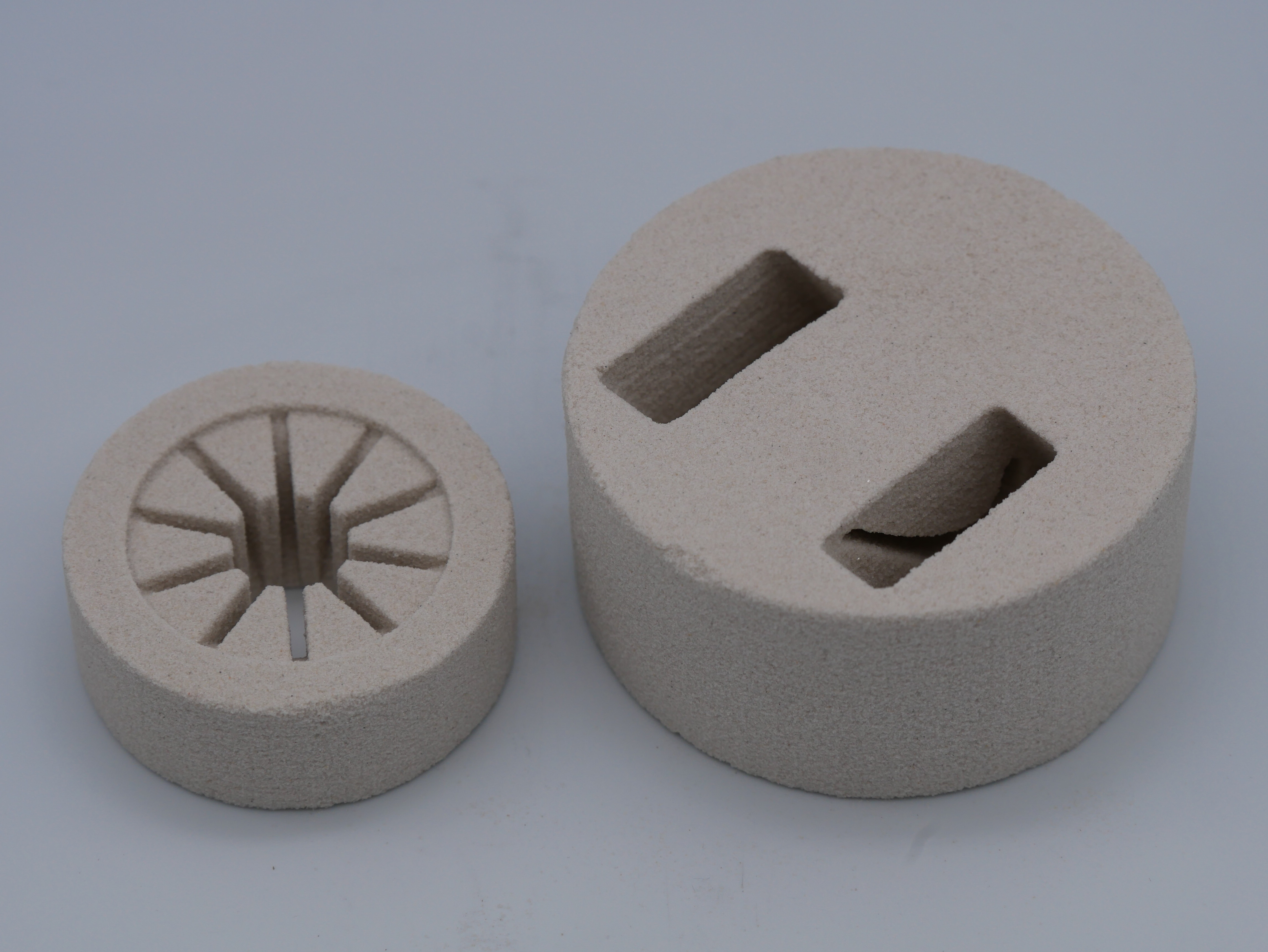

Video - FAST/SPS & Additive Manufacturing: Counterform Technique

Representation of the hybridization process of FAST/SPS with additive manufacturing.

All rights reserved to Norimat, any copy or use without the mention of Norimat is forbidden.

Le luxe et l'innovation par Spark Plasma Sintering (French content)

Webinaire

Norimat: Peut-on innover dans le secteur du luxe grâce à l’utilisation de la technologie Spark Plasma Sintering ?

Par Bastien Nodenot, notre responsable projets matériaux pour notre division luxe et expert en Spark Plasma Sintering technologie.

Video - Optimize Thermal Gradients and Part Microstructure in the FAST/SPS Process Through Multiphysics Simulation

Spark Plasma Sintering Online Conference

Dr. Jennifer Mackie, Head of Modeling and Digital Product Development at Norimat, expert in thermo-mechanical modeling.

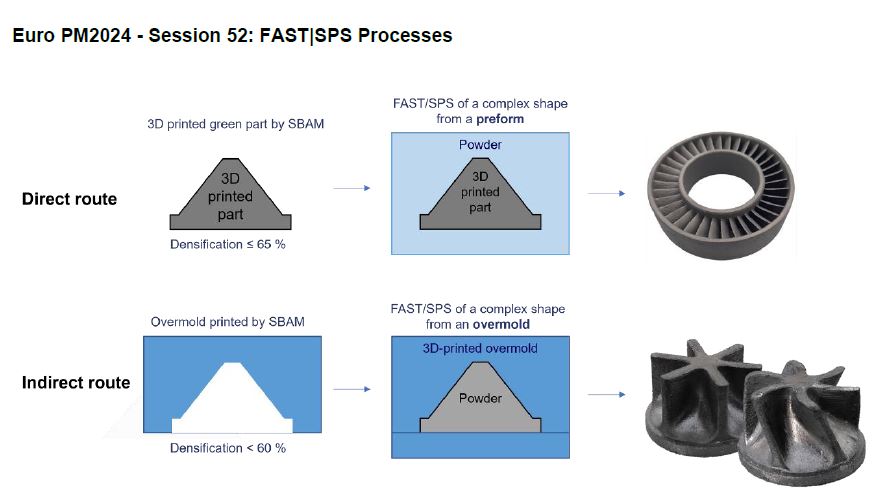

EuroPM2024 FAST/SPS , Norimat Paper

Euro PM2024 - Session 52: FAST|SPS Processes

Sinter Based Additive Manufacturing (SBAM) processes are receiving much attention as an alternative to LPBF processes for the rapid production of metal and ceramic components with reduced cost and environmental impact. On the other hand, the sintering step is sometimes difficult to perform for green parts from SBAM process resulting in high residual porosity. This paper proposes a versatile alternative with FAST/SPS hybridisation.

(French) Norimat ouvre une usine pour répandre la céramique ultra réfractaire dans l'industrie

septembre 2024

Reportage. La start-up toulousaine Norimat va investir près de 10 millions d'euros dans une usine dans la Ville rose. Cette enveloppe doit permettre à la jeune pousse de s'attaquer au marché de l'industrie aéronautique et spatiale, ainsi que la filière nucléarire. Pour ce faire...

(French) A Toulouse, Norimat prêt à industrialiser sa technologie d'impression 3D

30 septembre 2024

La deeptech toulousaine Norimat, qui développe une technique d'impression 3D innovante, figure parmi les lauréats de la 6ème vague de l'appel à projets "première usine" du plan France 2030...

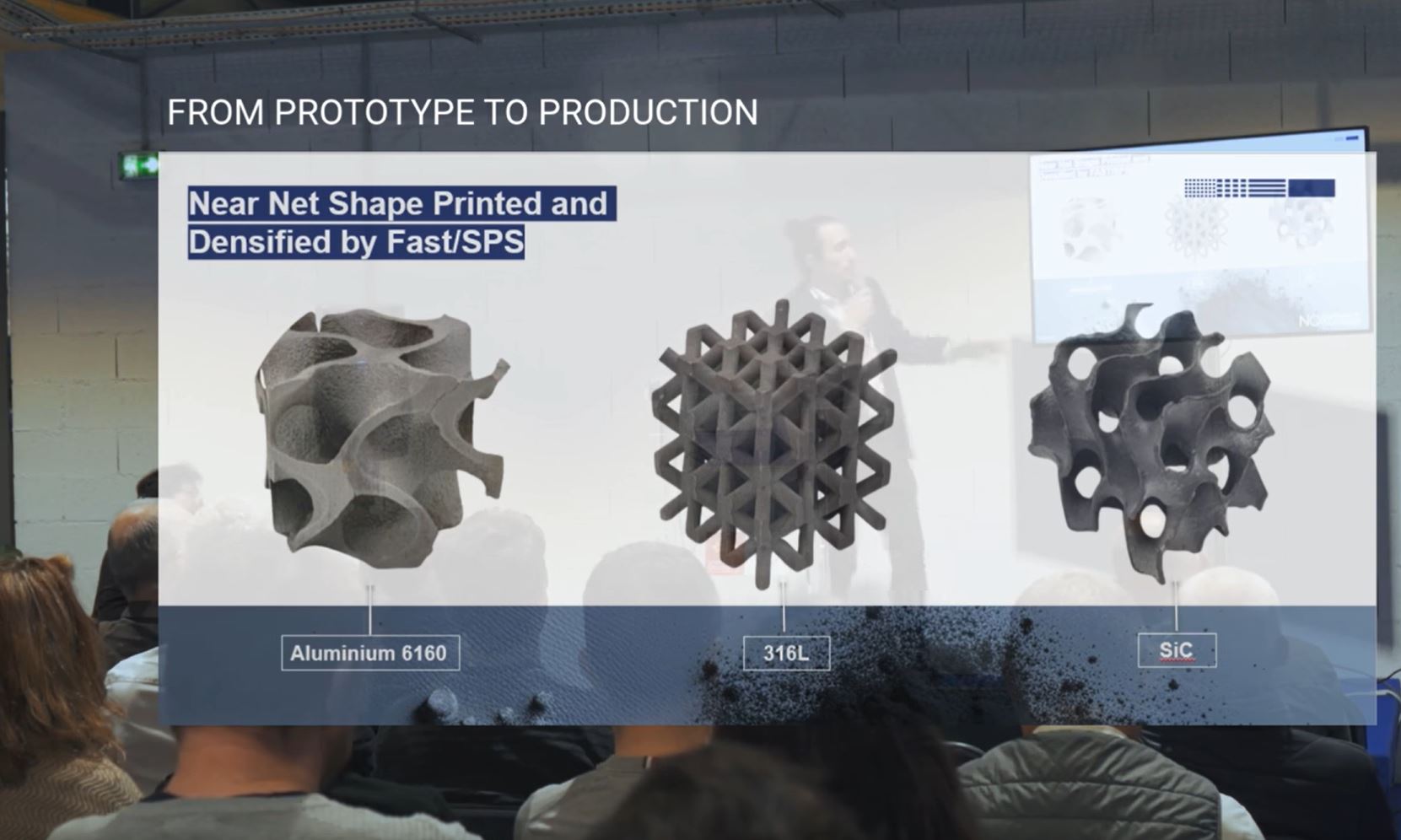

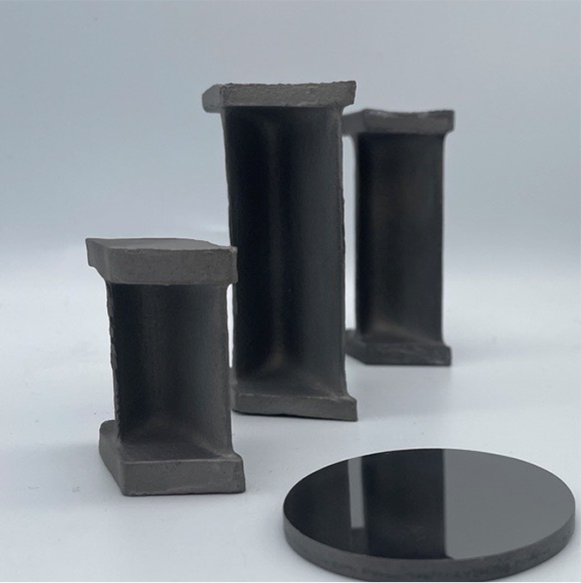

Video - FAST/SPS predicted size up parts

Mold Design for FAST/SPS

That is the main reason why we have developed Mold Design for FAST/SPS ..."

How do we ensure the quality of parts with the correct mold dimensions to obtain a homogeneous microstructure ?

"We believe that digital tools are the missing piece of the puzzle.

Video - FAST/SPS process - VIDEO

Video representation of the SPS process

All rights reserved to Norimat, any copy or use without the mention Norimat is forbidden.

FAST/SPS & Additive Manufacturing: Preform Techique

Representation of the hybridization process of FAST/SPS with additive manufacturing.

All rights reserved to Norimat, any copy or use without the mention of Norimat is forbidden.

FAST/SPS TIAL CYLINDER TO BLADE

Fully Dense Near Net Shape TiAl BLADES <1H

How to Industrialize and Manufacture FAST/SPS Sintered Near Net Shape Parts with New Numerical Tools

All rights reserved to Norimat, any copy or use without the mention Norimat is forbidden.

CERAMICS

From ancient art to the parts that allow cars to brake and space shuttles to fly...

All rights reserved to Norimat, any copy or use without the mention Norimat is forbidden

Why aim for a small thermal gradient?

It is now well-known that Spark Plasma Sintering (SPS) can produce high-performance samples with higher material properties compared to conventional processes...

All rights reserved to Norimat, any copy or use without the mention Norimat is forbidden

Homogeneous microstructure during the size up of FAST/SPS samples:

Use case with UHTC composite

All rights reserved to Norimat, any copy or use without the mention Norimat is forbidden

Receive the file by email

Use your work email address, Gmail, Yahoo, Hotmail, Live and other non-work addresses are not accepted.